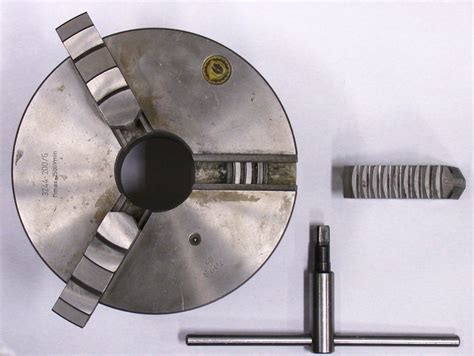

chuck in cnc machine A CNC chuck is a specialized clamp used in machining to hold a workpiece firmly on a machine tool, particularly a lathe machine. Its job is to secure the workpiece and ensure it can be accurately machined without . From glossy US comedies to gritty Brit dramas, Netflix is stuffed with great shows. Here's our pick of the best Netflix box sets to binge.QUICKFIX- JB3 - Maintenance-free junction (Includes Wago) DESIGNED FOR USE WITH WAGO 221 SERIES CONNECTORS. Specifications. Designed for .

0 · what is solid chuck

1 · what is a chuck engineering

2 · types of collet chucks

3 · strong lathe chucks

4 · replacement chucks for cnc machines

5 · power chucks for cnc lathes

6 · kitagawa chuck catalogue

7 · chuck jaws for kitagawa

Delta Aluminum Single-Lid, Deep, Full-Size Crossover Truck Box, Black - 1-301002

What Is a CNC Chuck? A CNC chuck is a type of chuck specifically designed for use with Computer Numerical Control (CNC) machines. It is a clamping device that holds a workpiece securely in place during machining or cutting .A self-centering chuck, also known as a scroll chuck, uses dogs (usually called jaws), interconnected via a scroll gear (scroll plate), to hold onto a tool or workpiece. Because they most often have three jaws, the term three-jaw chuck without other qualification is understood by machinists to mean a self-centering three-jaw chuck. The term universal chuck also refers to this type. These chuc.A CNC chuck, also known as a lathe chuck, is a specialized device used in computer numerical control (CNC) machining. It is an essential component of a lathe machine and is used to securely hold and rotate the workpiece during . A CNC chuck is a specialized clamp used in machining to hold a workpiece firmly on a machine tool, particularly a lathe machine. Its job is to secure the workpiece and ensure it can be accurately machined without .

Vacuum Chucks, Fixtures, and Clamping Systems can be awesome productivity enhancers in any shop, but they're especially helpful for rapid prototyping and sheet work (e.g. .

A collet chuck’s low-profile design provides better tool clearance and allows machining to take place very close to the chuck face. This ability to work closer to the chuck can also help prevent thin parts from sagging or bending. You must keep your chuck well lubricated, ideally with proper chuck grease, to have consistent grip and accuracy. The lower the chucking pressure the more care and attention . When properly matched to a machine, bar feeder and application, CNC collet chucks provide an economical and effective way of holding material less than 4 inches in diameter.

Standard Manual Chucks suit to a high-mixture of work pieces and low-volume production. High performance Rotary Cylinder is integral to for the operation of a power chuck and extracts the maximum capability of the chuck. Compact & .

Most CNC lathes for use with power chucks have A2 spindle noses. Some others may have a camlock nose or an L taper nose, but generally the ones with those noses use a .What Is a CNC Chuck? A CNC chuck is a type of chuck specifically designed for use with Computer Numerical Control (CNC) machines. It is a clamping device that holds a workpiece securely in place during machining or cutting operations performed by the CNC machine.A CNC chuck, also known as a lathe chuck, is a specialized device used in computer numerical control (CNC) machining. It is an essential component of a lathe machine and is used to securely hold and rotate the workpiece during machining operations.A chuck is a specialized type of clamp used to hold an object with radial symmetry, especially a cylinder. In a drill, a mill and a transmission, a chuck holds the rotating tool; in a lathe, it holds the rotating workpiece. [1] Chucks commonly use jaws to hold the tool or workpiece.

A CNC chuck is a specialized clamp used in machining to hold a workpiece firmly on a machine tool, particularly a lathe machine. Its job is to secure the workpiece and ensure it can be accurately machined without slipping or vibrating. When properly matched to a machine, bar feeder and application, CNC collet chucks provide an economical and effective way of holding material less than 4 inches in diameter. Vacuum Chucks, Fixtures, and Clamping Systems can be awesome productivity enhancers in any shop, but they're especially helpful for rapid prototyping and sheet work (e.g. signs and electical panels). This guide shows you how to use them to best effect. Here’s a CNC lathe work holding thumb rule that tells you when you can hold in a chuck, when to use a tailstock, and when to use a steady, based on the L/D (Length to Diameter) ratio of the part. Chuck only: Use if L/D is less than 3.

Three jaw chuck refers to self-centering chuck, its jaws are interconnected via a scroll gear and move at the same time, while jaws on four-jaw chucks move independently and require operators to center the workpiece.

what is solid chuck

what is a chuck engineering

In summary, compensation chucks play a crucial role in CNC machining by enabling precision performance through accurate alignment, secure clamping, and compensating for workpiece.

Generally, chuck is divided into three jaw chuck or four jaw chuck from its structure. And according to the different clamping mode, it can also be divided into the hydraulic chuck, pneumatic chuck, and electric chuck.

What Is a CNC Chuck? A CNC chuck is a type of chuck specifically designed for use with Computer Numerical Control (CNC) machines. It is a clamping device that holds a workpiece securely in place during machining or cutting operations performed by the CNC machine.

A CNC chuck, also known as a lathe chuck, is a specialized device used in computer numerical control (CNC) machining. It is an essential component of a lathe machine and is used to securely hold and rotate the workpiece during machining operations.

A chuck is a specialized type of clamp used to hold an object with radial symmetry, especially a cylinder. In a drill, a mill and a transmission, a chuck holds the rotating tool; in a lathe, it holds the rotating workpiece. [1] Chucks commonly use jaws to hold the tool or workpiece. A CNC chuck is a specialized clamp used in machining to hold a workpiece firmly on a machine tool, particularly a lathe machine. Its job is to secure the workpiece and ensure it can be accurately machined without slipping or vibrating. When properly matched to a machine, bar feeder and application, CNC collet chucks provide an economical and effective way of holding material less than 4 inches in diameter. Vacuum Chucks, Fixtures, and Clamping Systems can be awesome productivity enhancers in any shop, but they're especially helpful for rapid prototyping and sheet work (e.g. signs and electical panels). This guide shows you how to use them to best effect.

Here’s a CNC lathe work holding thumb rule that tells you when you can hold in a chuck, when to use a tailstock, and when to use a steady, based on the L/D (Length to Diameter) ratio of the part. Chuck only: Use if L/D is less than 3. Three jaw chuck refers to self-centering chuck, its jaws are interconnected via a scroll gear and move at the same time, while jaws on four-jaw chucks move independently and require operators to center the workpiece.

In summary, compensation chucks play a crucial role in CNC machining by enabling precision performance through accurate alignment, secure clamping, and compensating for workpiece.

types of collet chucks

strong lathe chucks

The Truck-Lite 50600 junction box features a larger internal area and 50% more harness ports. This makes it easier to expand and work on the electrical connections.

chuck in cnc machine|kitagawa chuck catalogue